NEW X-TRACT

COMING MAY 2022

X-TRACT

Trailblazing Design.

Legendary Performance.

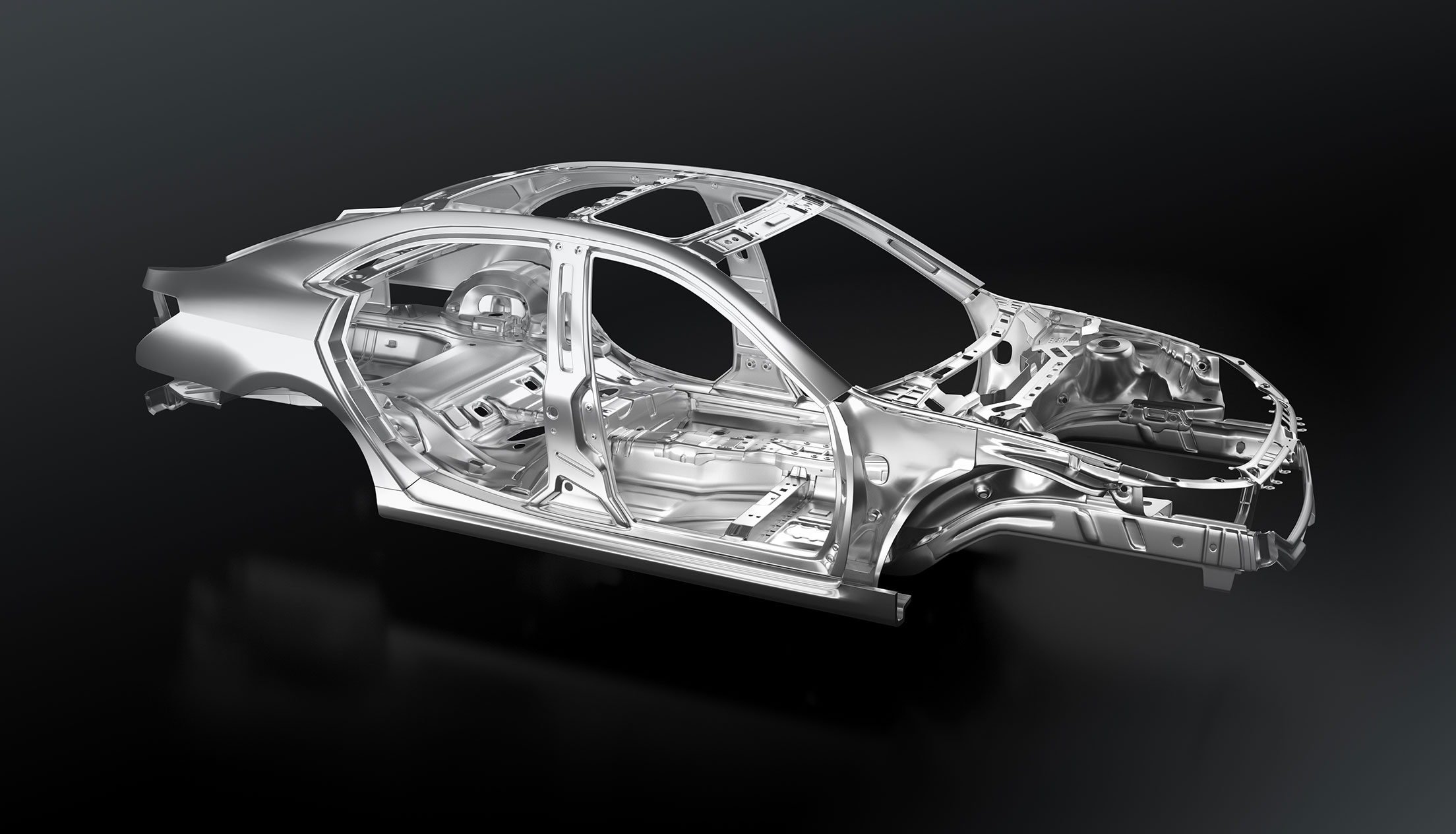

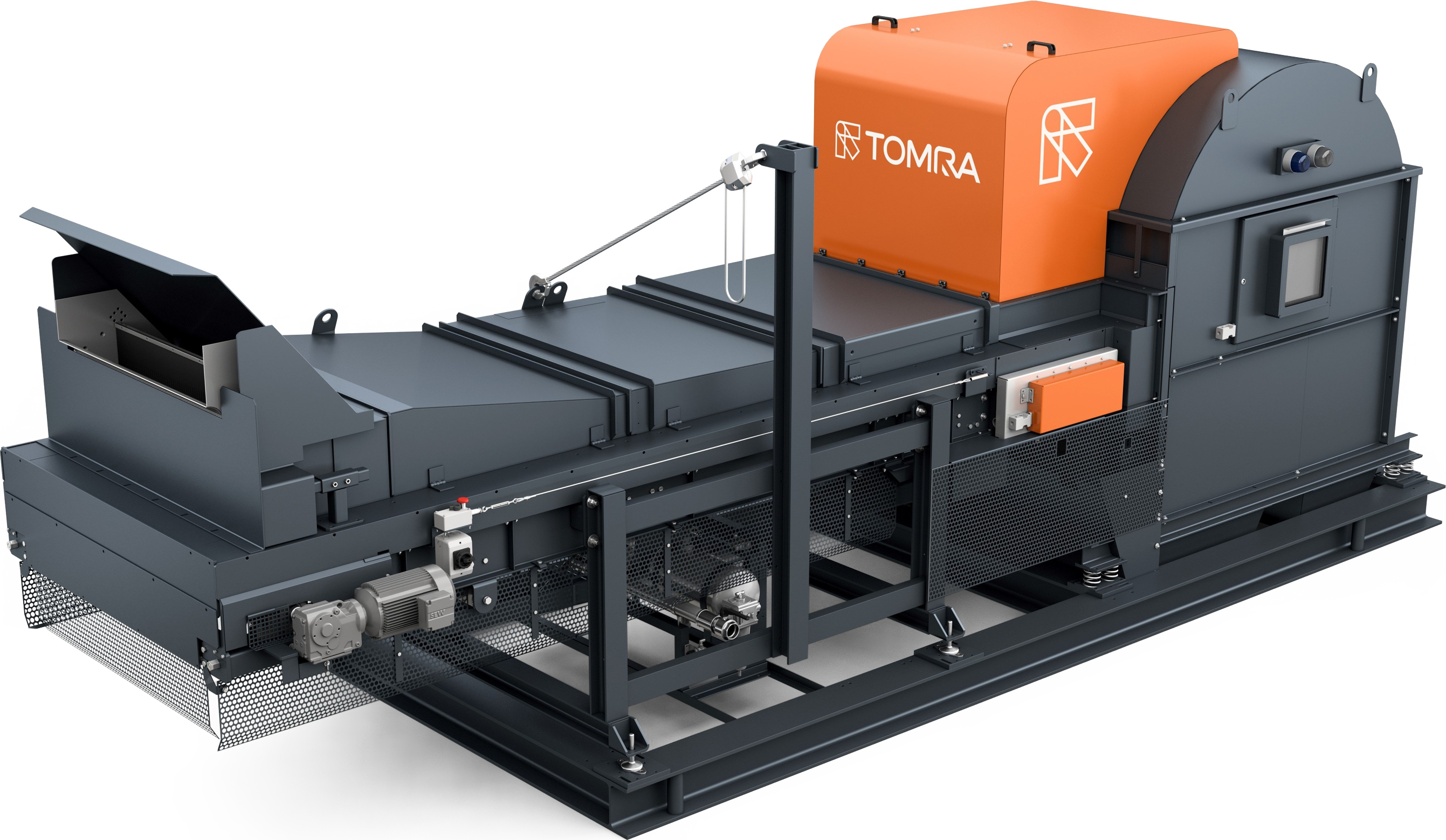

Designed for high performance sorting of aluminum from heavy metals, X-TRACT’s original top-down set up and optimal source-to-sensor positioning provide unparallel sharp detection and fast integration time. Built to withstand even the harshest environments, the high throughput sorting machine harnesses the power of dual energy x-ray transmission imaging with high resolution sensors and data-driven software development.

Since all the mechanics, software and sensors are developed in-house by TOMRA, X-TRACT delivers unrivaled throughput and sorting accuracy. With intelligent decision-making software engineered specifically to process primary and secondary raw materials, operators benefit from high purity and high throughput aluminum sorting.

TOP MOUNTED

X-RAY SOURCE

POWERFUL,

HIGH THROUGHPUT

PROCESSING

SENSOR & SOFTWARE

DEVELOPED BY TOMRA

HIGH RECOVERY

AND/OR HIGH PURITY

SORTING

MULTIPLE SORTING

TASKS & GRAIN SIZES

X-TRACT is the world’s leading XRT sorting technology for aluminum recycling and processing, serving key players in 34 countries. With a deep understanding of industry trends in metal recycling and smelting, we designed the new X-TRACT to set new standards in aluminum sorting once again.

In early May, we’ll reveal the machine that will accelerate green aluminum and the circular economy. With an enhanced design, machine intelligence, and future-proof performance, the new X-TRACT continues our legacy as the global leader in high throughput, high purity aluminum sorting.

ALWAYS AHEAD OF THE CURVE

Client Success

Enabling Bottom-

Line Growth

CENTRO ROTTAMI

In Italy, three TOMRA X-TRACT sorting units are used at Centro Rottami to efficiently process and purify about 1,500 tons of aluminum each month. From old window profiles, the company produces high grade secondary aluminum for its neighboring billet foundry.

MARKET OUTLOOK

The demand for recycled aluminum is projected to more than double by 2050. As a global leader in maximizing the performance of post-consumer aluminum for both scrap recyclers and smelters, see why the industry turns to TOMRA X-TRACT to meet future demand.

Milestones

XRT Legacy

NEW X-TRACT

METALS

In May, a new generation sorting system that separates aluminum from heavy metals is coming – stay tuned!

MAGNESIUM

REMOVAL

Advanced low-density detection for the separation of magnesium and super lights from mixed metal streams.

ALUMINUM FINES

& COPPER WIRE

New generation fines sorting unit recovers 5 – 40mm high value fractions, half the size previously possible.

1758 CARAT

DIAMOND

One of the world’s largest diamonds recorded in history (352 grams) recovered by TOMRA XRT technology.

GERMAN

DESIGN AWARD

X-TRACT awarded special mention in industrial design category for successful aspects and design solutions.

DIAMOND

MINING

Karowe Mine in Botswana selects TOMRA XRT technology for diamond and kimberlite recovery.

E-SCRAP

SORTING

Removal of brominated flame retardants from e-scrap waste that also required less x-ray energy (max. 90keV).

ALUMINUM

SORTING

Aluminum from heavy metals with high resolution or high sensitivity sensor module. 500W and 1000W versions.

Contact

Metal Performance,

Accelerated.

Are you looking to increase profitability with high purity secondary aluminum? Perhaps you’re a smelter interested in reducing energy and CO2 emissions? Get ahead of the curve to meet the increasing demand for green aluminum. Our global team of metal industry experts can offer you valuable insights for optimizing aluminum processes with TOMRA X-TRACT. We look forward to hearing from you!