OBTAIN™

Obtain deeper insights. Achieve higher purity. AI-powered ore sorting

Explore the future of AI ore sorting

OBTAIN™ - A groundbreaking deep learning technology for TOMRA's sorters, revolutionizes ore sorting by enabling precise detection and classification of individual particles, even when clustered. OBTAIN™ is an industry-first: single-particle precision in high-throughput ore sorting. This revolutionary software uses a Neuronal Network to identify the properties of each particle accurately and independently of the sorter’s capacity, achieving unparalleled precision and reliability in detection and ejection. Based on their specific requirements, the mining operation has the flexibility to either enhance the throughput of the sorter while maintaining consistent sorting efficiency or improve sorting precision without compromising the existing throughput. It is a true game changer.

"OBTAIN™ proves advantageous for a fully operational mine by enhancing recovery rates and elevating product quality within the existing throughput. Furthermore, this innovative technology has the capability to unlock untapped value from low-grade ore, waste dumps, or materials previously deemed uneconomical for processing."

Stefan Jürgensen

Software team lead | TOMRA Mining

Benefits

Elevating efficiency and value of sorting operations

OBTAIN™ proves advantageous for a fully operational mine by enhancing recovery rates and elevating product quality within the existing throughput. Conversely, in mines with additional capacity, it facilitates increased throughput without compromising product quality. Furthermore, this innovative technology has the capability to unlock untapped value from low-grade ore, waste dumps, or materials previously deemed uneconomical for processing.

Enhancing Precision with Insightful Data and Predictive Maintenance

OBTAIN™ will also add value to a mining operation with a wealth of extremely detailed and accurate data, such as precise online particle-size distribution of the feed. When used in combination with TOMRA Insight, it can provide the customer with detailed reporting on the performance of the sorter and its components to help them optimize the process, as well as enable them to plan for predictive maintenance.

“AI and deep learning will give us amazing opportunities for the future by improving sorting performance and add significant value to the mineral processing industry.”

Albert du Preez

SVP | TOMRA Mining

Developed for XRT machines

The OBTAIN™ software has been developed for TOMRA’s XRT sorters. It will be available on new models, but there will also be an upgrade package available for existing machines, providing a significant opportunity for customers already operating TOMRA XRT sorters, to substantially enhance the sorting performance where it proves to be a suitable solution.

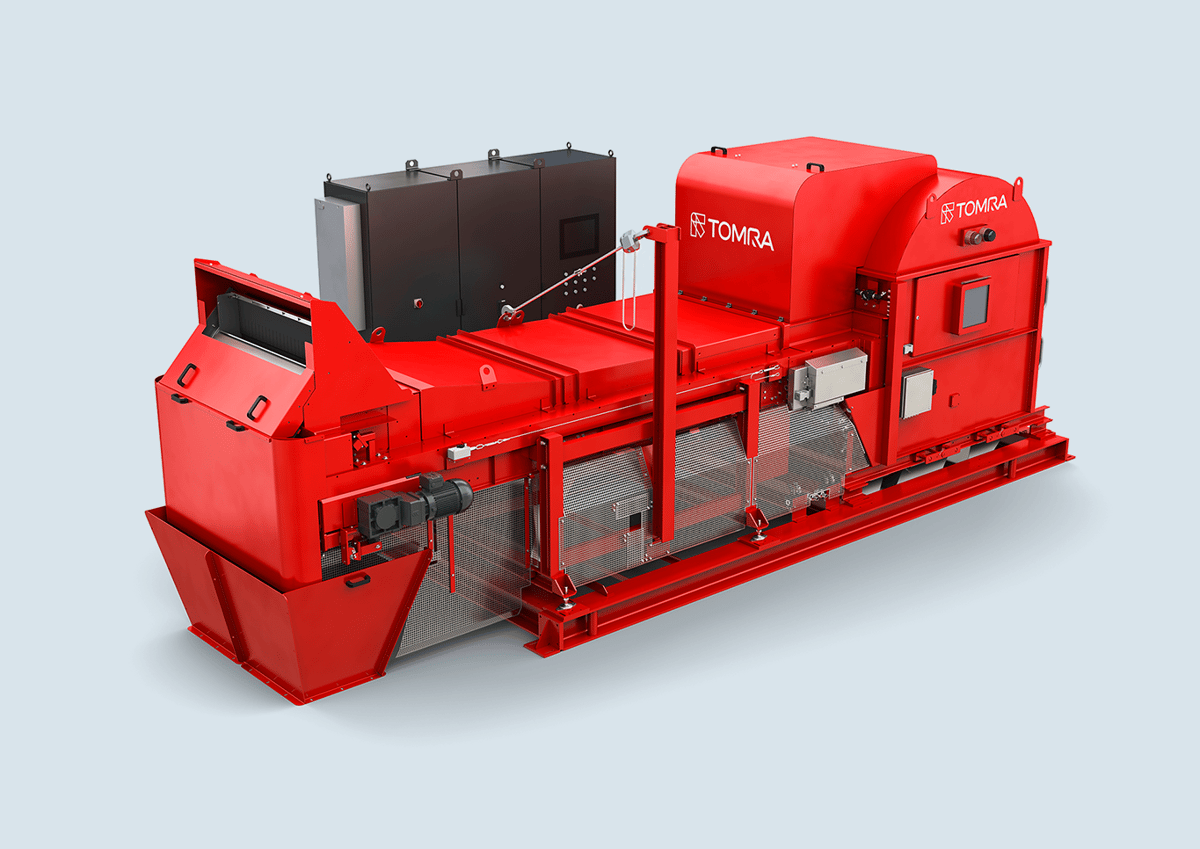

COM Tertiary XRT

The COM Tertiary XRT features very precise detection and ejection especially for smaller particle sizes. The mechanical setup is specialized for this material and is equipped with high performing, low energy consumption and precise air ejection valves. The proprietary image processing ensures a unique recovery rate.

COM XRT 2.0

The COM XRT 2.0 features higher belt speed and throughput, which translate directly into increased productivity in mineral processing. A more powerful X-Ray system accommodates the sorting of larger-sized material due to better X-Ray penetration. For this larger-sized material it offers increased wear resistance and longer component lifetime, with quick and safe maintenance through providing easier access to replaceable components.

Deep Learning explained

AI encompasses two sub-fields that have considerably progressed in recent years: Machine Learning, which recognizes patterns, learns from data and improves without being programmed, and Deep Learning, which is a type of Machine Learning that uses artificial neural networks to analyze data and solve complex problems. These technologies process vast amounts of data very quickly and use it to make decisions without human intervention.

Machine Learning and Deep Learning can further improve the sorting process for mining operations that are already using sensor-based sorting, but also open new opportunities by enabling the processing of very low-grade materials that previously would have been discarded. A further advantage of AI is the vast amount of data it generates and processes, which provides mining operations with valuable insights into the sorter’s performance and for predictive maintenance.