CONTAIN™

Reveal what rocks contain. Unlock hidden value.

Revolutionizing the recovery of inclusion type ore

Industry-first innovation for inclusion-type ore sorting. An AI-powered sorting system that lets you see deeper, sort smarter, and recover more. The future of inclusion-type ore classification. CONTAIN™ is more than an AI-feature - it's a revolution in ore sorting intelligence. By applying deep learning to XRT data, it detects valuable inclusions within rocks even when buried deep inside - revealing what traditional sorting can't.

CONTAIN™ gives you clarity where there was uncertainty

Most sorting systems work with what they see, CONTAIN™ with what it understands. By using deep learning, it detects inclusion-type ores like tin, tungsten, nickel, copper and sulfides - helping miners unlock value previously lost in the tailings stream. Transform unknows into insights. Transform ore variability into opportunity. Transform buried value into measurable output. CONTAIN™ doesn't just sort - it thinks. it sees beyond the surface to detect what others can't, making your plant smarter, leaner, and more profitable.

“We were absolutely overwhelmed by what CONTAIN™ could do. It immediately changed the way we think about sorting and processing. This isn’t just an upgrade – it’s a completely new level of performance”

David Comtesse

Production Manager | Wolfram Bergbau

Benefits

Transforming pattern recognition into operational value

Unlike traditional optical sorting systems, which often struggle to detect low-grade or inclusion-type ores, CONTAIN™ introduces a fundamentally different approach to classification. By analyzing the structure of each rock using advanced deep learning algorithms, the system identifies subtle mineralogical patterns that indicate the presence of valuable metals such as tungsten, nickel or tin. Each rock is assigned a probability score based on its likelihood of containing subsurface mineralization, enabling precise, data-driven sorting decisions. This capability allows mining operations to adapt their strategies in real time – whether the goal is to maximize concentrate grade, minimize valuable material loss, or align with processing cost constraints.

Sorting Performance across ore grades

CONTAIN™ has been engineered to handle a wide spectrum of ore grades – from high-value deposits to low-grade, large rocks with sparse inclusions that have historically been difficult to process efficiently. Conventional sorting systems can be configured to detect some low-grade material, but they tend to let large volumes of gangue enter the product stream, diluting output and eroding profitability. By contrast, CONTAIN™ uses deep learning to classify mineralizations with exceptional accuracy, enabling precise sorting thresholds that make the recovery of low-grade ores economically viable.

"Our sorters now empowers customers with intuitive control over sorting performance. Using a single slider, they can fine-tune the balance between product purity and recovery to meet their specific economic needs, achieving optimal performance without compromise."

Stefan Jürgensen

Software team lead | TOMRA Mining

Developed for XRT machines

The CONTAIN™ software has been developed for TOMRA’s XRT sorters. It will be available on new models, but there will also be an upgrade package available for existing machines, providing a significant opportunity for customers already operating TOMRA XRT sorters, to substantially enhance the sorting performance where it proves to be a suitable solution.

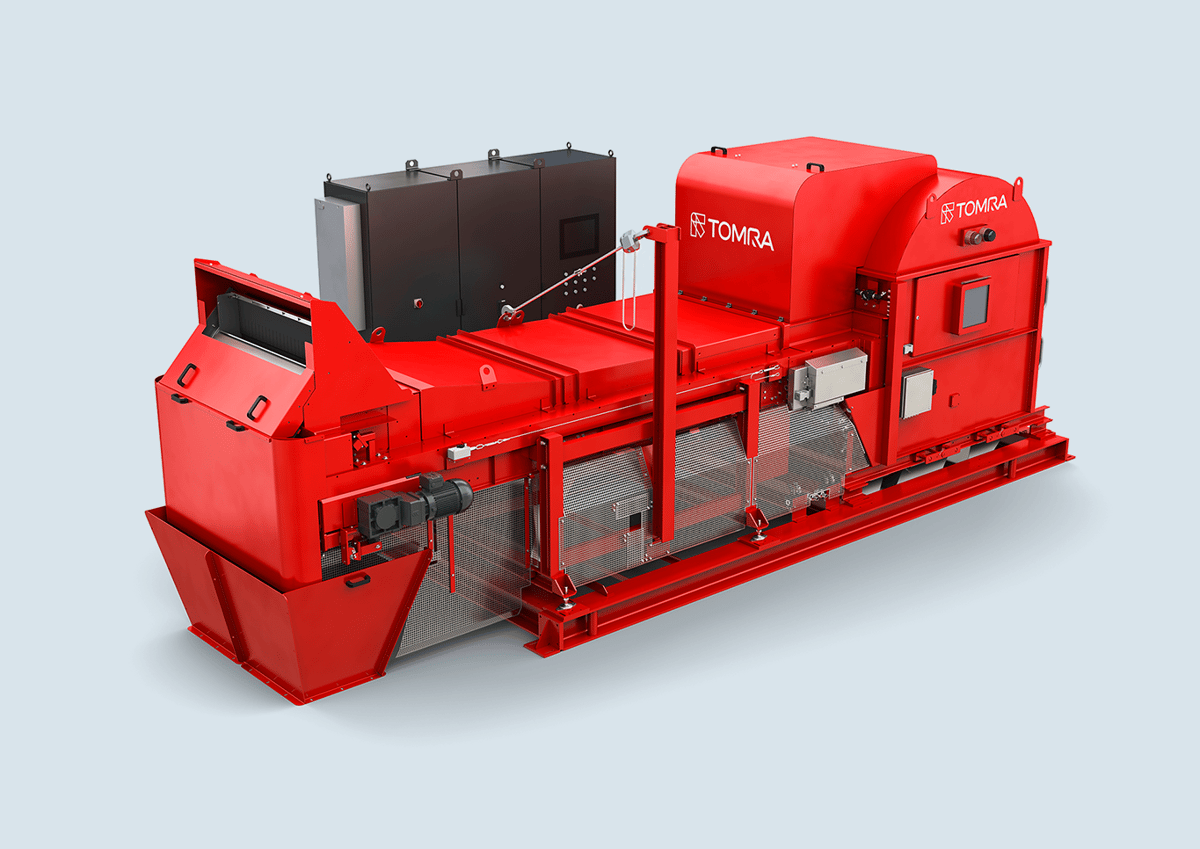

COM Tertiary XRT

The COM Tertiary XRT features very precise detection and ejection especially for smaller particle sizes. The mechanical setup is specialized for this material and is equipped with high performing, low energy consumption and precise air ejection valves. The proprietary image processing ensures a unique recovery rate.

COM XRT 2.0

The COM XRT 2.0 features higher belt speed and throughput, which translate directly into increased productivity in mineral processing. A more powerful X-Ray system accommodates the sorting of larger-sized material due to better X-Ray penetration. For this larger-sized material it offers increased wear resistance and longer component lifetime, with quick and safe maintenance through providing easier access to replaceable components.

Deep Learning explained

AI encompasses two sub-fields that have considerably progressed in recent years: Machine Learning, which recognizes patterns, learns from data and improves without being programmed, and Deep Learning, which is a type of Machine Learning that uses artificial neural networks to analyze data and solve complex problems. These technologies process vast amounts of data very quickly and use it to make decisions without human intervention.

Machine Learning and Deep Learning can further improve the sorting process for mining operations that are already using sensor-based sorting, but also open new opportunities by enabling the processing of very low-grade materials that previously would have been discarded. A further advantage of AI is the vast amount of data it generates and processes, which provides mining operations with valuable insights into the sorter’s performance and for predictive maintenance.